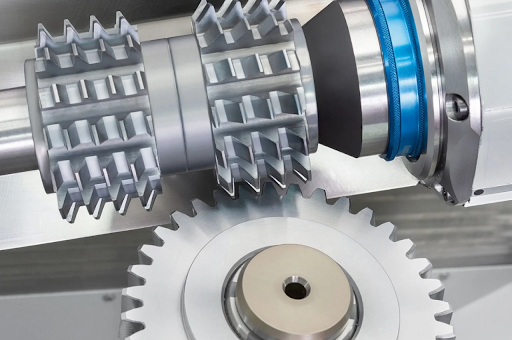

The tool looks simple, yet with every turn it carves out a perfect gear tooth. That was the point of recognising why have reached the backbone of gear making. They are not just tools; they are the reason devices keep running smoothly day after day. The best thing you’ll ever notice is that they are so well made. The edges and nooks are absolutely made with precision.

What makes hobbing different?

Cutting a gear might sound easy, but it is far from it. With hobbing, the cutter works in a rolling action, which means every tooth comes out uniform. That kind of precision is hard to match with other processes. Whether it is a small spur gear or a complex helical one, hobbing gets it right. And because the method is quick, manufacturers can handle bulk orders without losing accuracy.

Why good cutters matter

Here is the truth. If a gear is off even by a fraction, the whole machine suffers. Noise, heat, and early wear all come from poor cutting. A reliable saves that headache. Think about the automobile industry, where thousands of gears go into vehicles daily. A single defect can turn into thousands of repair complaints. That is why industries trust cutters that deliver consistent quality.

India’s role in the global market

Over the last decade, have stepped into the spotlight. They are no longer just suppliers for local markets. Numerous are now shipping to Europe, the US, and Asia. The reasoning is simple: they connect affordable pricing with a level of precision that holds up to global standards. Some are even experimenting with advanced coatings and CNC technology that make cutters last longer and work faster.

Signs of a dependable manufacturer

If you are sourcing hobs, a few signs always help:

- The cutters hold their edge after long runs.

- Delivery timelines are respected.

- Customisation is possible when gear designs are unusual.

- Re-sharpening and support services are part of the package.

- Pricing is fair, but not at the cost of quality.

A company that offers these is not just a supplier. It is a partner that helps production lines keep moving without stress.

Why the shift to India is growing

It is not only about cost savings. Clients are turning to gear hob manufacturers in India because they find steady quality and openness to innovation. Many of these firms listen to customer needs and adjust quickly. That kind of flexibility makes a huge difference when industries work on tight schedules.

Gears may look easy, but after each one lies detailed work with the suitable tools. The need for powerful, precise tools is growing, and so is the demand for reliable cutters. By counting the right gear hobs and the expertise of Indian plants, industries can reduce downtime, cut repair costs, and keep their machines flying longer. Periodically, the least tool in the procedure is the one that creates Pinay Flex the biggest impact.